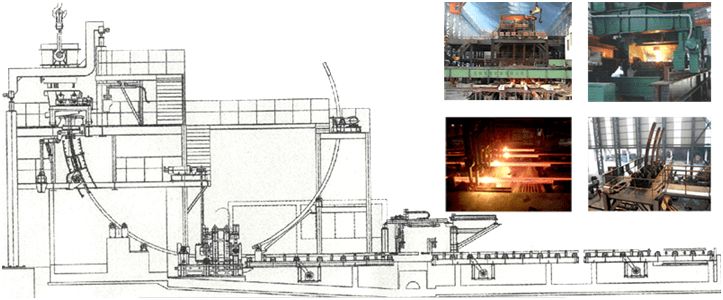

CCM continuous casting machine

Continuous casting is a casting method in which the melt is continuously poured from the end of the tundish to the mold. The steps of freezing and exiting the product are continuous and the dimensions of the mold limit the dimensions of the production billet. Continuous casting technology is used for ferrous and non-ferrous alloys. Depending on the mold positions (vertical or horizontal) continuous casting machines They are also called vertical or horizontal.

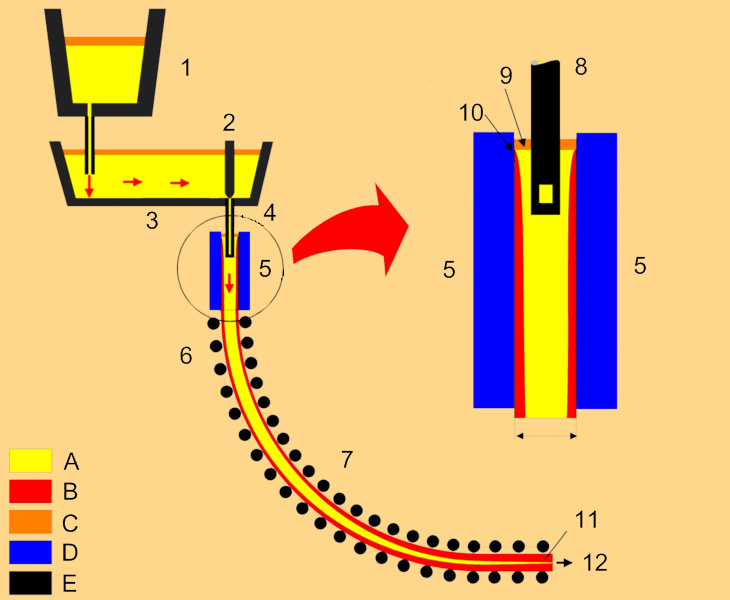

General process of continuous casting system

The continuous casting product should not only be accurate in terms of dimensions, but should also be diverse in terms of quality. From its qualitative aspects, it can be mentioned that it is clean, does not have surface cracks, and does not have impurities as follows.

In rapid solidification continuous casting, the flotation of non-metallic contents in strands is relatively delayed. These contents can lead to the formation of weak or lax joints that cause more problems in the process.

Vertical continuous casting

Steel casting is usually done in vertical continuous machines . In this method, the molten metal is continuously poured from the end at a constant speed and weight (by keeping the molten surface under control) into the mold, which is a copper mold and is cooled with water (primary cooling zone). The cooling of the melt causes the shape of the solid to take parallel to the vertical movement . The oscillating motion of the mold prevents it from sticking to the melt.

When the casting product comes out of the mold, it is cooled in the secondary cooling zone of water (or water with air) which is sprayed on the casting surface.

- 1. Transferring the melt from the furnace to the furnace

- 2. Transferring the melt from the mold to the mold

- 3. Billet formation by copper mold

- 4. Billet transfer with a crescent puller

- 5. Guide the billet by the hydraulic rollers of the load

- 6. Billet transfer to the cooling system by water sprinklers