12 MW power plant (ccp)

By exploiting this system, which is implemented next to the sponge iron unit, the furnace output heat will feed the boiler of the power plant instead of being left in the space. Green or renewable.

Unique feature and benefits of 12 MW power plant

Feed from furnace heat

This power plant has a unique feature, which is the use of furnace output heat in the sponge iron production unit of Bisotoun Steel complex.

- • Use of heat recovery to produce steam

- • Production of 12 megawatts of continuous electricity

- • Synchronous capability to the national electricity grid

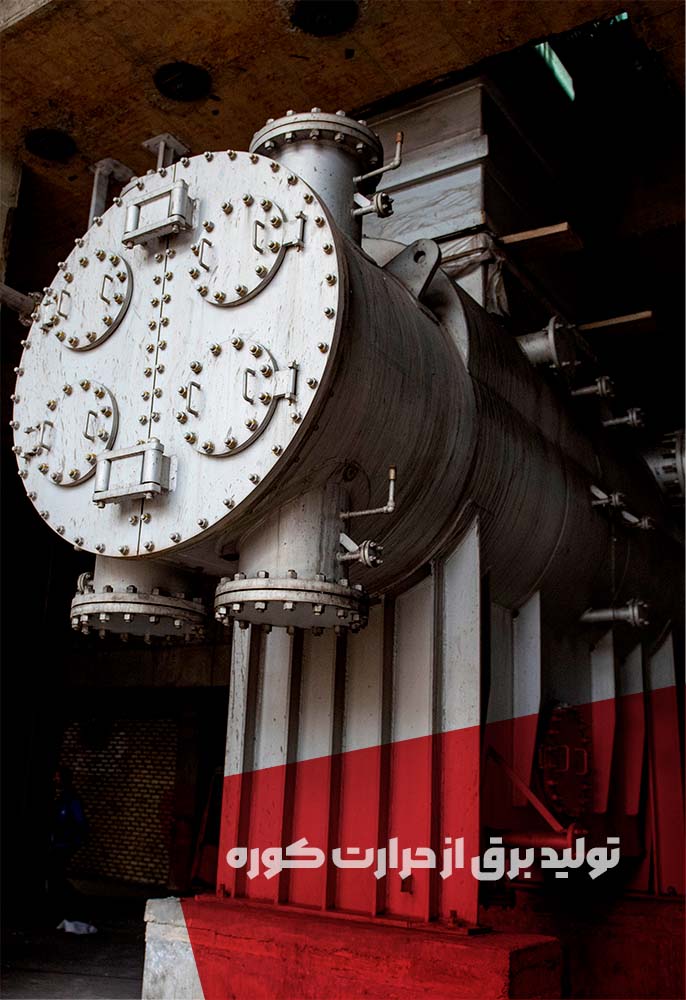

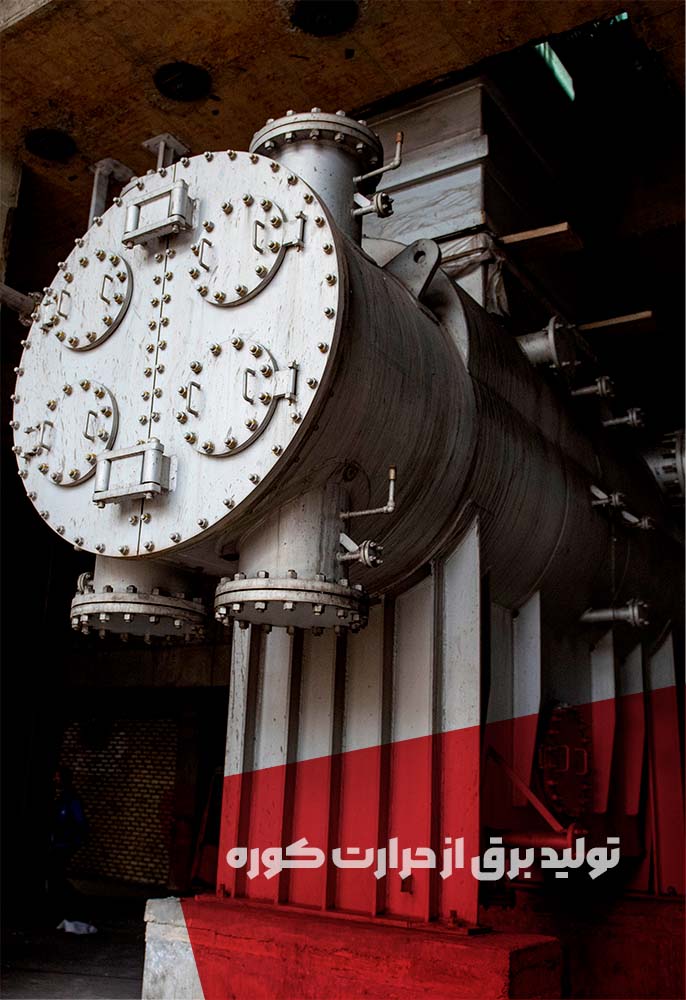

The process of generating electricity from the heat of a 500-ton furnace

In this unit, the heat of the gases from the sponge iron production process is transferred from the 500 ton furnace to the boiler, absorbs heat and turns into superheat steam with high pressure.

The steam input to the turbine, which has a temperature of 475 degrees Celsius and a steam pressure of 63 atmospheres, must be in order to make the turbine rotate up to 6000 revolutions, the rotation of the turbine drives the gearbox and this gearbox rotates the generator up to 1500 revolutions per minute and produces electricity in It is about 12 megawatts, which has the ability to be synchronized with the national power grid.