فرآيند SL/RN

Input iron ore: in the form of lumps or pellets

Regenerative agent: Do not coke coal

Type of regeneration furnace: Rotary Kiln

Regeneration temperature: about 1000 to 1100 degrees Celsius

History of the process: since around 1980

Optimum capacity: one hundred thousand tons for each module

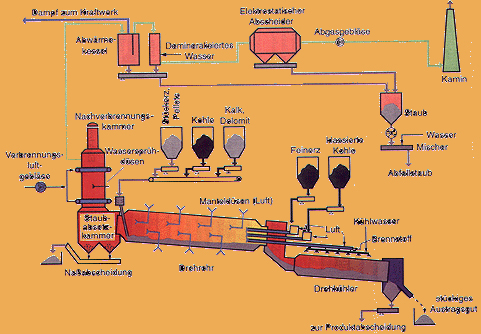

SL/RN process The SL/RN process is a method that uses rotary kilns in this method. Its initial research dates back to after the Second World War, when various European and American companies participated in the formation of this method, and the name of this process originates from this. It is taken that the first letter of each is the name of one of these companies. But most of the research has been done in Germany by Lurgi.

The production technology in the rotary kiln has been designed and started working before the sponge iron with the cement and lime production process. In fact, the production of iron in these optimized furnaces is the same as the production process of cement and lime.

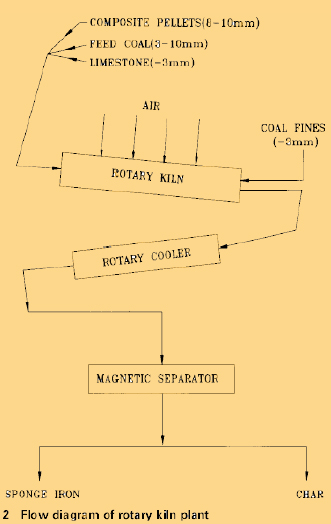

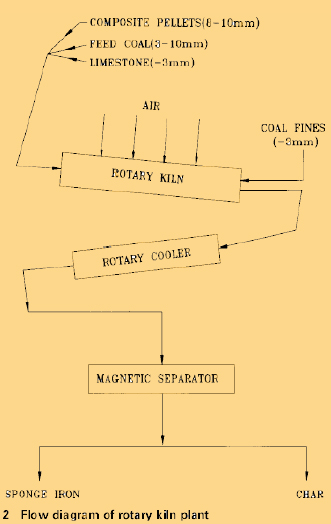

In this process, iron ore is introduced in the form of lumps or pellets along with coke and some lime and dolomite to adjust the amount of mojo in the coal from one side of the horizontal rotary furnace. The regeneration furnace is a horizontal furnace with an inclination of about 5 degrees.

The charged materials are preheated in the first part of the furnace and in the second part they are revived to 92 degrees of metal.

After leaving the furnace, the hot regenerated materials enter a rotary annealing furnace to lower their temperature, then after leaving the cooling furnace and passing under the magnetic separator, the metal materials are separated from the ash and stored or smelted to the arc furnace should be moved.

The iron ore used in the rotary furnace in this method does not have the sensitivity of vertical furnaces due to the lack of pressure in the lumps of the charge material, and it is possible to use all kinds of iron ore with a lump size between 6 and 20 mm in this furnace. The lumps move continuously and slowly inside the horizontal rotating furnace. Generally, raw slag is a mixture of iron ore, soft coal and jasper, which has a better result at the end of the stage.

Generally, raw slag is a mixture of iron ore, soft coal and jasper, which has a better result at the end of the stage. The used coal is very available because it is cheap and cannot be converted into coke. The coal used can have up to 30% of volatile substances and its licarbon should not be less than 45%.

Dolomite is also added to charging materials due to reducing the effect of sulfur in coal, and it also accelerates regeneration operations.

The horizontal rotary furnace is the most important part of the regeneration unit. This furnace consists of a steel cylinder with a diameter of 3 to 6 meters and a length of 25 to 80 meters. The inside is bricked and the furnace is installed on the rotating gears with a gentle slope of 3-5 degrees. . The temperature of the regeneration zone is about 1075 degrees Celsius. Due to the increase in the temperature of the furnace, coal powder is injected from the outlet end of the furnace into the interior of the furnace, and at certain intervals a series of valves are designed to blow process air for better burning of coal and production of CO CO gas for regeneration. Hot process gas with some free air from this The valves are injected into the furnace.